Introduction to Offset Meat Smokers

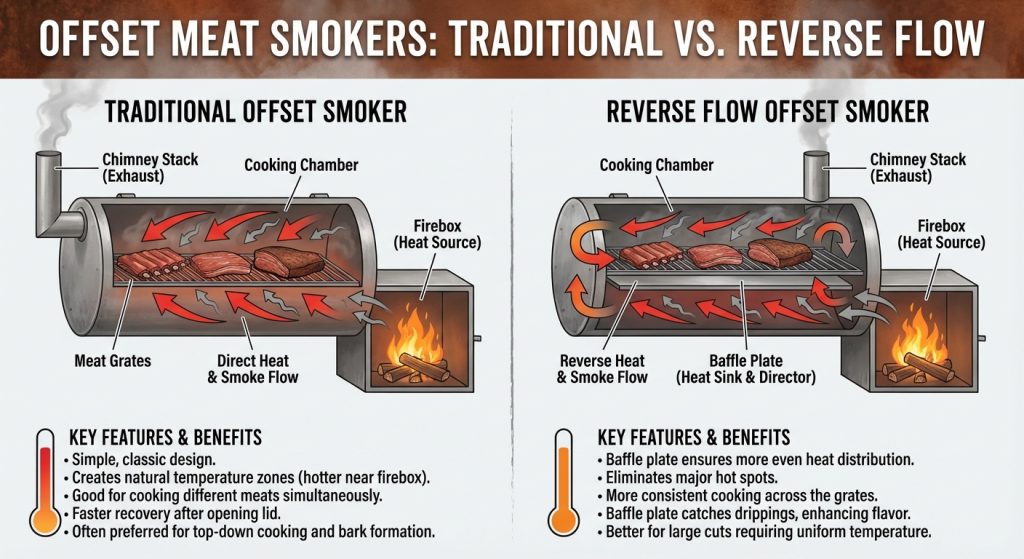

Traditional vs reverse flow smokers differ in how heat and smoke travel through the cooker, impacting temperature consistency and flavor profile.

Offset meat smokers are iconic in American BBQ, known for their traditional low-and-slow cooking. Within this popular category, a crucial distinction exists between traditional offset smokers and reverse flow smokers.

Understanding the differences between these two designs is key, as it impacts everything from temperature consistency to the flavor profile of your smoked meats. Whether you’re a beginner shopping for your first offset meat smoker or an experienced pitmaster considering an upgrade, knowing how these designs compare will help you make an informed decision.

This article will delve into the structural differences, performance characteristics, and practical considerations that set traditional offset smokers apart from their reverse flow counterparts.

What Is a Traditional Offset Meat Smoker?

A traditional offset meat smoker features a horizontal cooking chamber with a firebox attached to one side. This classic design has been the backbone of BBQ for generations, representing authentic low-and-slow cooking.

The basic operation is straightforward: you build a fire in the offset firebox using wood, charcoal, or a combination of both. Heat and smoke travel directly from the firebox into the main cooking chamber through a connecting opening.

Traditional Offset Smoker Components and Airflow

Key components include:

- The firebox (where fuel burns)

- The cooking chamber (where meat sits on grates)

- The chimney or exhaust stack (typically positioned on the opposite end from the firebox)

In a standard offset smoker, air flows in a relatively direct path. It enters through vents in the firebox, travels horizontally through the cooking chamber, and exits through the chimney.

What Is a Reverse Flow Offset Smoker?

A reverse flow offset smoker takes the basic offset design and adds a strategic modification that fundamentally changes how heat and smoke move through the cooking chamber.

The defining feature of a reverse flow smoker is a metal baffle plate (also called a tuning plate) that runs beneath the cooking grates along the length of the chamber. This plate creates a deliberate pathway that redirects smoke and heat.

How Reverse Flow Offset Smokers Work

Instead of flowing directly from firebox to chimney, smoke is forced downward under the baffle plate, travels the full length of the cooking chamber, then rises back up at the far end before exiting through the chimney—which is repositioned near the firebox rather than at the opposite end.

This extended, reversed smoke path gives the design its name and creates a distinctly different cooking environment compared to traditional offset meat smokers.

Traditional vs. Reverse Flow: Key Structural Differences

Understanding the structural disparities is crucial when comparing traditional offset vs. reverse flow smokers.

Firebox Position and Design

Both traditional offset and reverse flow smoker types position the firebox to one side of the cooking chamber, typically at the same height or slightly lower than the cooking surface.

The main difference lies in how the firebox connects to the chamber. Traditional offsets have a simple opening that allows direct entry. Reverse flow models may have a modified connection designed to work seamlessly with the baffle plate system.

Baffle Plate System (Core Design Difference)

This is the most significant structural difference between these two offset meat smoker designs.

Traditional offset smokers have no baffle plate. The cooking chamber is open from firebox to chimney, with grates suspended above for placing meat.

Reverse flow smokers feature a thick metal plate positioned below the cooking grates. This plate spans most of the chamber length, leaving a gap at the end opposite the firebox where smoke can rise.

The baffle serves multiple purposes:

- Directing smoke flow

- Distributing heat

- Protecting meat from direct radiant heat

Chimney and Exhaust Placement

In traditional offset smokers, the chimney is located at the end opposite the firebox. This placement creates a natural draft that pulls smoke across the cooking surface.

Reverse flow smokers position the chimney near the firebox end, often on the same side. This counterintuitive placement makes sense when you understand the reversed smoke path—smoke travels down, along the bottom, and back before exiting near where it entered.

Heat Distribution and Temperature Consistency

Heat distribution differences represent one of the most practical distinctions between these offset meat smoker types, directly impacting smoker temperature consistency.

Traditional Offset Smoker Heat Patterns

Traditional offset smokers typically have a pronounced temperature gradient. The area closest to the firebox runs significantly hotter—sometimes 50-75°F warmer—than the far end near the chimney.

The middle section falls somewhere between these extremes. This difference matters when cooking multiple pieces of meat or when precision is important.

Reverse Flow Smoker Heat Distribution

Reverse flow smokers are known for their enhanced temperature consistency. The baffle plate acts as a heat diffuser, absorbing thermal energy and radiating it more evenly across the entire cooking surface.

Temperature variations typically stay within 15-25°F across the grates. The baffle plate also shields meat from direct radiant heat from the firebox, preventing the intense heat exposure that can dry out or overcook the side facing the fire.

In a traditional offset, you might need to rotate meat periodically or strategically place different cuts in hot and cool zones. Reverse flow designs significantly reduce or eliminate this need.

Smoke Flow Patterns and Flavor Development

The journey smoke takes through each smoker type affects both flavor development and cooking characteristics, including the much-desired smoke ring.

Traditional Offset Smoke Path

In traditional offset smokers, smoke follows a direct horizontal path from firebox to chimney. It passes over the meat once in a relatively straight line, spending less total time in the chamber before exhausting.

Reverse Flow Smoke Journey

Reverse flow systems force smoke through an extended journey. Smoke enters, travels downward, runs the full length of the chamber underneath the baffle, rises at the far end, passes over the meat, and then travels back toward the chimney.

This path is roughly twice as long. The extended smoke exposure in reverse flow smokers can produce a more pronounced smoke ring—the pink layer just beneath the meat’s surface prized in BBQ.

However, smoke flavor intensity depends on many factors beyond flow pattern alone, including wood type, fire management, and cooking duration.

Cooking Performance Differences

Temperature Control and Responsiveness

Both traditional offset and reverse flow smokers require active fire management, but they respond differently to adjustments.

Traditional offset smokers react more quickly to changes in fuel or airflow. Adding wood or adjusting vents produces relatively immediate temperature shifts. This responsiveness can be advantageous for experienced pitmasters but challenging for beginners trying to maintain steady temperatures.

Reverse flow smokers have greater thermal mass due to the thick baffle plate. This mass creates more temperature stability—beneficial for long cooks—but also means the smoker responds more slowly to adjustments.

Changes take longer to manifest, requiring a more patient, anticipatory approach. Both designs have learning curves, but they favor different skill sets.

Cooking Capacity, Efficiency, and Fuel Use

Usable cooking space is similar between comparable-sized units, though the baffle plate in reverse flow models slightly reduces vertical clearance between grates and the chamber bottom.

Fuel consumption often runs slightly higher in reverse flow smokers. The additional thermal mass of the baffle plate requires more initial energy to heat up, and maintaining that mass at temperature consumes ongoing fuel.

Heat-up time definitely favors traditional offsets. Without a baffle plate to heat, they reach cooking temperature faster—sometimes 30-45 minutes quicker than comparable reverse flow models.

Food Quality Results (Moisture, Bark, Smoke)

When properly managed, both offset meat smoker types produce excellent BBQ, though with subtle differences.

Reverse flow smokers typically provide better moisture retention. The baffle plate prevents direct heat exposure and creates a slightly more humid environment, helping meat stay juicier through long cooking sessions.

Bark formation—the flavorful crust on smoked meat—develops well on both types but may form slightly faster on traditional offsets due to more direct heat and airflow exposure.

Flavor profiles are remarkably similar when variables like wood choice and fire management are controlled. The extended smoke path in reverse flow adds slightly more smoke penetration, but this difference is subtle.

Advantages of Traditional Offset Smokers

Traditional offset smokers offer several practical benefits that appeal to many BBQ enthusiasts.

Lower Cost and Simpler Design

Cost represents a significant advantage. Without the additional baffle plate and associated modifications, traditional offsets typically cost 20-30% less than comparable reverse flow models.

The simpler design means fewer components to maintain, clean, or potentially replace. There’s an elegance to the straightforward approach that resonates with purists.

Lighter Weight, Portability, and Faster Heat-Up

Weight differences matter for portability. Without the heavy baffle plate, traditional offsets are substantially lighter—sometimes 50-100 pounds less in comparable sizes.

This makes them easier to move, position, or transport to competitions or gatherings. Faster heat-up times mean you can go from cold smoker to cooking temperature more quickly, valuable when you want to start smoking without extensive preheating.

Advantages of Reverse Flow Smokers

Reverse flow designs bring their own compelling benefits to the table, particularly regarding smoker temperature consistency.

More Even Temperatures Across the Grates

Temperature consistency stands out as the primary advantage. More even heat distribution across the cooking surface simplifies the entire smoking process, reducing the need for constant monitoring and meat rotation.

The reduction of hot spots means more forgiving conditions. Meat positioned anywhere on the grates receives similar thermal treatment, eliminating the “problem zones” that exist in traditional offsets.

Better Moisture Retention and Beginner-Friendly Operation

Better moisture retention helps produce juicier results, particularly valuable for leaner cuts that are prone to drying out during extended cooking.

The more stable thermal mass contributes to a more forgiving smoking environment for beginners. Temperature fluctuations are less dramatic, giving novices more room for error while they develop fire management skills.

Disadvantages of Traditional Offset Smokers

Traditional offset smokers come with challenges that require skill and attention to overcome.

Uneven Heat Distribution and Hot Spots

Uneven heat distribution is the most cited drawback. Managing hot spots near the firebox and cooler areas at the far end requires strategic meat placement and often periodic rotation during long cooks.

These smokers demand more attention and active management. Maintaining consistent temperatures across the cooking surface while managing the direct smoke path requires experience and vigilance.

Steeper Learning Curve

The potential for dry spots—particularly on the side of meat facing the firebox—means careful positioning and monitoring are essential for optimal results.

The learning curve is steeper. Beginners often struggle with temperature management and uneven cooking before developing the skills to master these smokers.

Disadvantages of Reverse Flow Smokers

Despite their advantages, reverse flow smokers have notable drawbacks.

Higher Cost and Heavier Build

Higher cost is immediate and unavoidable. The additional materials and more complex construction translate directly to a heftier price tag.

Heavier construction affects portability and positioning. The thick baffle plate adds substantial weight, making these smokers more permanent fixtures than mobile cooking tools.

Longer Heat-Up Time and More Cleaning

Longer heat-up time tests patience, especially when you’re eager to start cooking. The thermal mass that provides stability during cooking also requires more time and fuel to reach target temperature initially.

The more complex design means more surfaces to clean and maintain, and the baffle plate can accumulate grease and residue that requires periodic attention.

Maintenance and Durability Considerations

Both offset meat smoker types require regular maintenance, but with different focuses.

Cleaning Requirements

Cleaning a traditional offset smoker involves removing ash from the firebox, scraping cooking grates, and occasionally removing buildup from chamber walls. The open design makes access relatively straightforward.

Reverse flow smokers require all the same attention plus baffle plate maintenance. Grease and residue accumulate on top of the baffle, and the space beneath can collect drippings.

Some designs allow baffle removal for thorough cleaning; others require cleaning in place, which can be awkward.

Long-Term Durability

Long-term durability depends more on construction quality than design type. Both styles can last decades with proper care, though the additional welds and joints in reverse flow designs create marginally more potential failure points.

Common wear points include firebox burn-through (in both types), warping from heat cycles, and rust from moisture exposure. The baffle plate in reverse flow smokers can warp over time if subjected to extreme temperature differentials.

How to Choose: Traditional Offset vs. Reverse Flow Smoker

Choosing between traditional offset and reverse flow smokers depends on your specific situation and priorities.

Skill Level and Experience

Skill level matters significantly. If you’re new to smoking, a reverse flow design offers more forgiving conditions and easier temperature management. Experienced pitmasters may prefer the responsive control of traditional offsets.

Budget and Cooking Style

Budget considerations are straightforward—traditional offsets cost less upfront. However, consider the learning curve cost in wasted meat and fuel while mastering a more challenging design.

Cooking style influences the decision. If you regularly smoke large quantities requiring every inch of grate space, reverse flow’s even heating is invaluable.

Portability and Smoking Frequency

If you need portability for competitions or moving your smoker seasonally, lighter traditional offsets offer practical advantages. For a permanent backyard installation, weight matters less.

Frequency also plays a role. Serious enthusiasts who smoke weekly may appreciate the efficiency and consistency of reverse flow. Occasional weekend warriors might not justify the extra investment.

Offset Smoker FAQ: Traditional vs. Reverse Flow

Does Reverse Flow Use More Fuel Than Traditional Offset?

Reverse flow smokers typically consume 10-20% more fuel due to the additional thermal mass of the baffle plate. The plate requires more energy to heat initially and maintains that heat throughout the cook.

However, the improved insulation effect can partially offset this difference during very long smoking sessions.

Can You Convert a Traditional Offset to Reverse Flow?

Converting a traditional offset to reverse flow is technically possible but rarely practical. It requires fabricating and installing a custom baffle plate, relocating the chimney, and potentially modifying the firebox connection.

The expense and effort typically exceed buying a purpose-built reverse flow smoker, and results may not match factory designs.

Which Type Produces Better BBQ Flavor?

When properly operated, both smoker types produce excellent BBQ with minimal flavor differences. Reverse flow provides slightly more smoke penetration due to the extended smoke path, but this difference is subtle.

Factors like wood selection, fire management, and cooking technique have far greater impact on flavor than smoker design alone.

Are Reverse Flow Smokers Worth the Extra Cost?

This depends on your situation. For beginners, the easier temperature management and more consistent results can justify the higher price by reducing the learning curve and improving early results.

Experienced pitmasters who’ve mastered traditional offsets may not find enough benefit to warrant the upgrade. Consider how much the more even heating and forgiving operation matter to your specific needs.

Do Competition Pitmasters Prefer One Type Over the Other?

Competition preferences are split. Some top pitmasters swear by reverse flow for consistency when cooking multiple identical entries. Others prefer traditional offsets for their responsive control and lighter weight for transport.

Success in competition depends far more on skill than equipment type—champions use both designs effectively.

How Much Does the Baffle Plate Affect Cooking?

The baffle plate dramatically impacts heat distribution, typically reducing temperature variance from 50-75°F to 15-25°F across the cooking surface.

It also shields meat from direct radiant heat, improves moisture retention, and extends the smoke path. These effects make reverse flow smokers fundamentally different cooking environments despite similar external appearance.

Which Type Is Better for Beginners?

Reverse flow smokers are generally more beginner-friendly. The even heat distribution forgives positioning mistakes, the stable thermal mass reduces dramatic temperature swings, and the protected cooking environment prevents some common problems.

However, beginners can certainly learn on traditional offsets with patience and dedication.

Can You Achieve the Same Results With Either Type?

Skilled pitmasters can produce excellent results with either design. Traditional offset users learn to manage hot spots through strategic meat placement and rotation.

The final BBQ quality depends more on the cook’s skill than the smoker design, though each type has a different learning curve and requires different techniques.

Key Takeaways: Traditional Offset vs. Reverse Flow

To summarize the essential differences between these two popular offset meat smoker designs:

- The fundamental structural difference between traditional offset and reverse flow smokers is the baffle plate system that redirects smoke through an extended path in reverse flow designs

- Traditional offset smokers cost less, weigh less, heat faster, and respond more quickly to adjustments, but have significant temperature gradients across the cooking surface

- Reverse flow smokers provide dramatically more even heat distribution, better moisture retention, and more forgiving cooking conditions, but cost more, weigh more, and take longer to reach temperature

- Neither design is inherently superior—the better choice depends on your budget, experience level, cooking frequency, and whether you value responsive control or consistent temperatures

- Beginners typically benefit from reverse flow’s forgiving nature, while experienced pitmasters may prefer traditional offsets’ direct control

- Both designs produce excellent BBQ when properly managed; success depends more on operator skill than equipment type

Conclusion: Choosing the Right Offset Smoker Design

The differences between traditional offset and reverse flow smokers go far beyond a simple baffle plate. These designs represent different philosophies in BBQ—one favoring simplicity and direct control, the other prioritizing consistency and forgiveness.

Understanding that traditional offsets offer direct smoke paths with pronounced heat gradients while reverse flow models provide extended smoke exposure with even heat distribution helps clarify which design suits your needs.

There’s no universally “better” option. A competition team traveling frequently might choose a lighter traditional offset. A backyard enthusiast feeding family gatherings might prefer the consistent results from reverse flow.